Technology

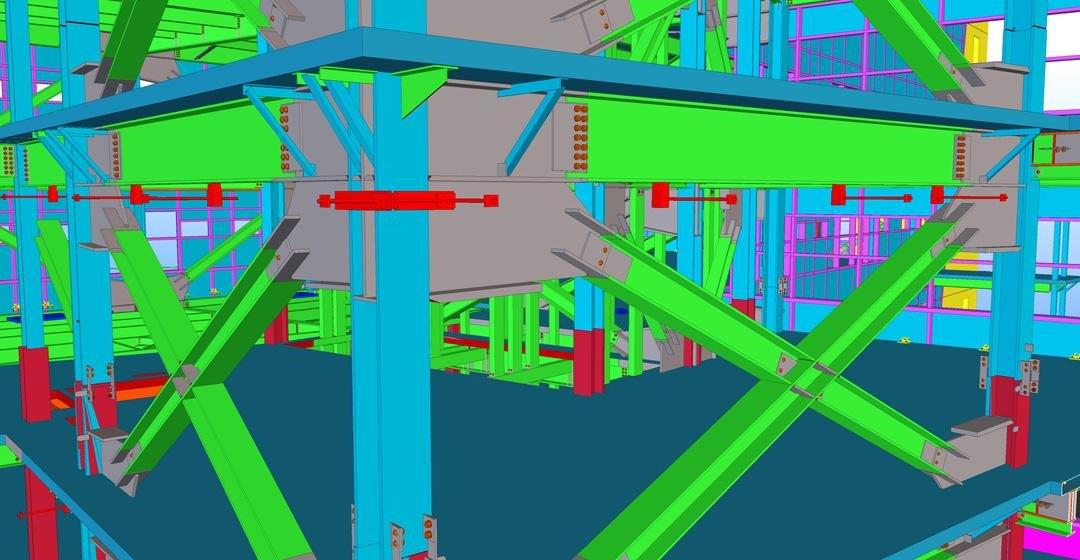

BIM Modeling – Detailing

Maintaining 15 to 20 internal full time detailing staff has required Olson Steel to invest aggressively in state of the art detailing capabilities to stay in sync with its general contractor partners and building owners. Olson’s historic investment in detailing technology has provided a strong competitive platform to be able to assist on the front […]

Corporate Technology

The Company just completed a major overhaul and upgrade to its internal servers/hardware and software programs corporate wide. The Company utilizes the full functionality of FABTROL in its estimating process and fully integrates its ERP System (SAGE Timberline) with its daily fabrication and erection operations. The Company continues to advance forward in leveraging its technology […]

Fabrication Process

Olson Steel continues to invest aggressively in state of the art fabrication equipment with enhanced CNC capabilities and direct integration between its detailing department and its CNC equipment. Technology is used to bridge direct communication and uploads from it’s San Leandro headquarters to it’s fabrication facilities in San Leandro and Fresno. The Company has established […]

Innovative Solutions

Olson Steel recognizes the innovative technological solutions developed by our employees through the Olson Company Award for Innovation. This program recognizes and rewards teams and individuals for implementation of innovative ideas that result in outstanding achievements within Olson.

Project Management and Field Erection

Olson Steel continues to place a strong emphasis on investing in the collaboration of technology between its Project Managers, Field Erectors and building partners. The Company has placed a strong emphasis on remaining at parity with its building partners as it relates to new technological advancement delivered at the job site or in the conference […]